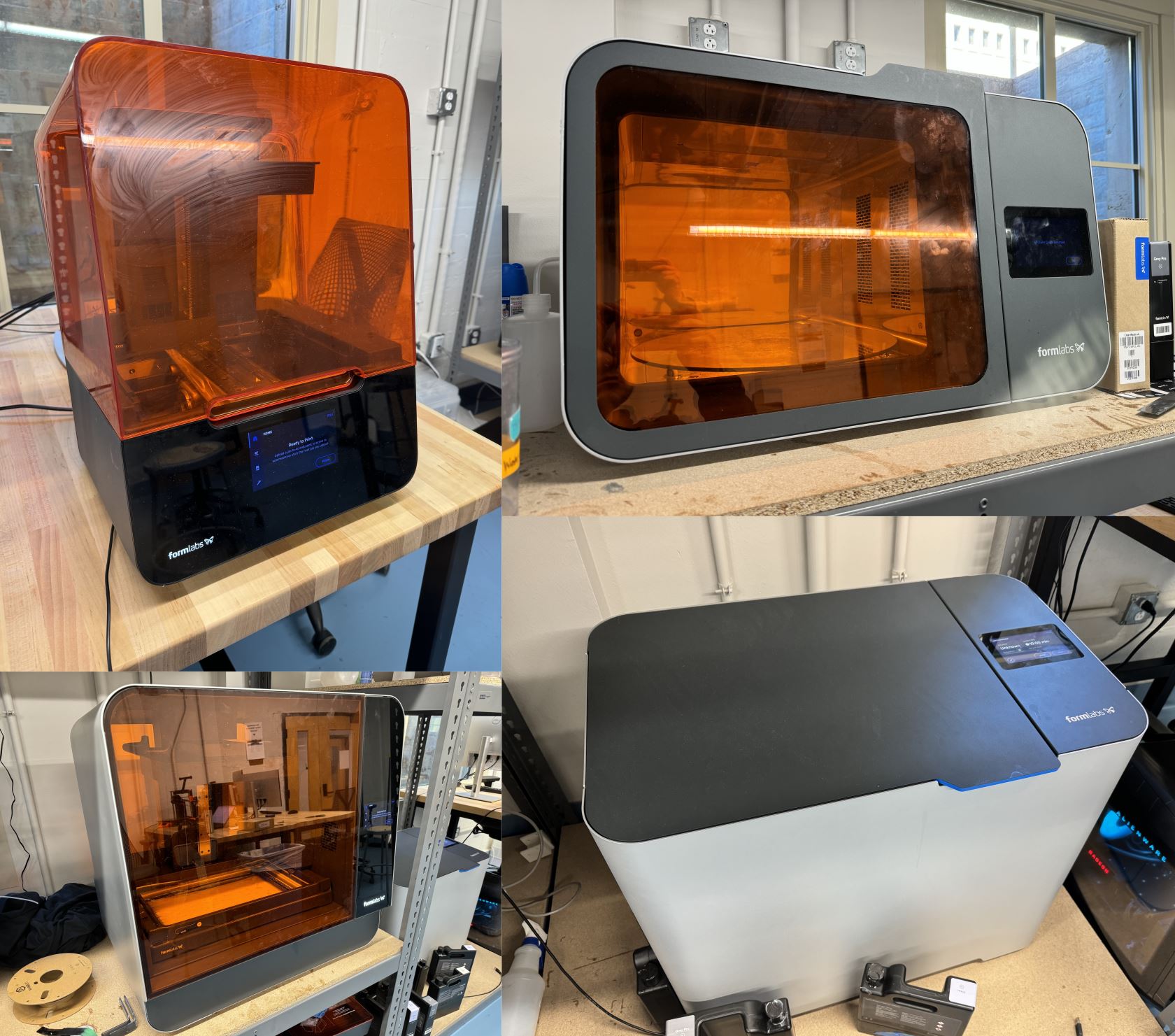

FormLabs 3D Printers

The FormLabs printers are SLA resin printers in the DigiFab lab. The advantage of resin printing is that there are a wider range of materials including flexible, rigid, ESD safe, and other materials. We have two different Formlabs printers in the DigiFab lab, the Form3+ and the Form3BL. Both printers function essentially the same, the only major difference being that the Form3BL has rougly double the print volume of the Form3+.

PreForm Slicer Walkthrough

PreForm Installation

PreForm is the slicer software for the Formlabs SLA printers.

Download PreForm here: PreForm

PreForm is supported on Windows and Mac.

PreForm Walkthrough

Like other 3D printer slicers, PreForm allows you to simply drag and drop your .STL file to add your part. From here, you can realign your part(s) on the bed. With SLA printing, it is recommended to NOT have your model directly contact the print bed but instead raise it using a support raft. To automatically set up your parts for printing, use the "One Click Print" button in the top right. This will align, rotate, and support your part(s) to allow them to print properly. From here, feel free to modify as you see fit. If you notice any errors in the bottom right, make sure to resolve those before proceeding.

When you are ready to print, make sure to select which resin material you would like to print with. You will also have the option to choose your resolution. Different resin materials will have different options. To see all of the available resin materials that can be used on the FormLabs printers, click below:

Removing and Cleaning a Part

Once a print is finished, you can remove the print bed and begin removing the part. Feel free to use the scraper near the FormLabs, just do not use scrapers that are not intended for resin printing as the resin residue may cause issues if transferred to the FDM printers.

Once your part is removed, you will need to clean it. To do this, it is reccomended to submerge in isopropyl alcohol for ~10 minutes, stirring occasionally. Once the washing station has been equiped with a suitable cleaning solution, you may also use that device to clean your parts. Note that IPA can be reused between parts, so it may be worth saving instead of throwing it away after every part.

Once your part is cleaned and dried, it can then be put in the curing station to finish. Simply place your part(s) in the curing station, select the material that they are made with, and press "Start." The curing station will automatically run a curing cycle. At the end of which, your parts should be fully cured and ready to go.

More Information

See more information on starting a SLA print on a FormLabs machine here: